COMPANY HISTORY

Mec.Ma.Srl was born as a natural progression of more than twenty years’ experience in precision mechanical manufacturing acquired by the founder in a company operating in the military sector.

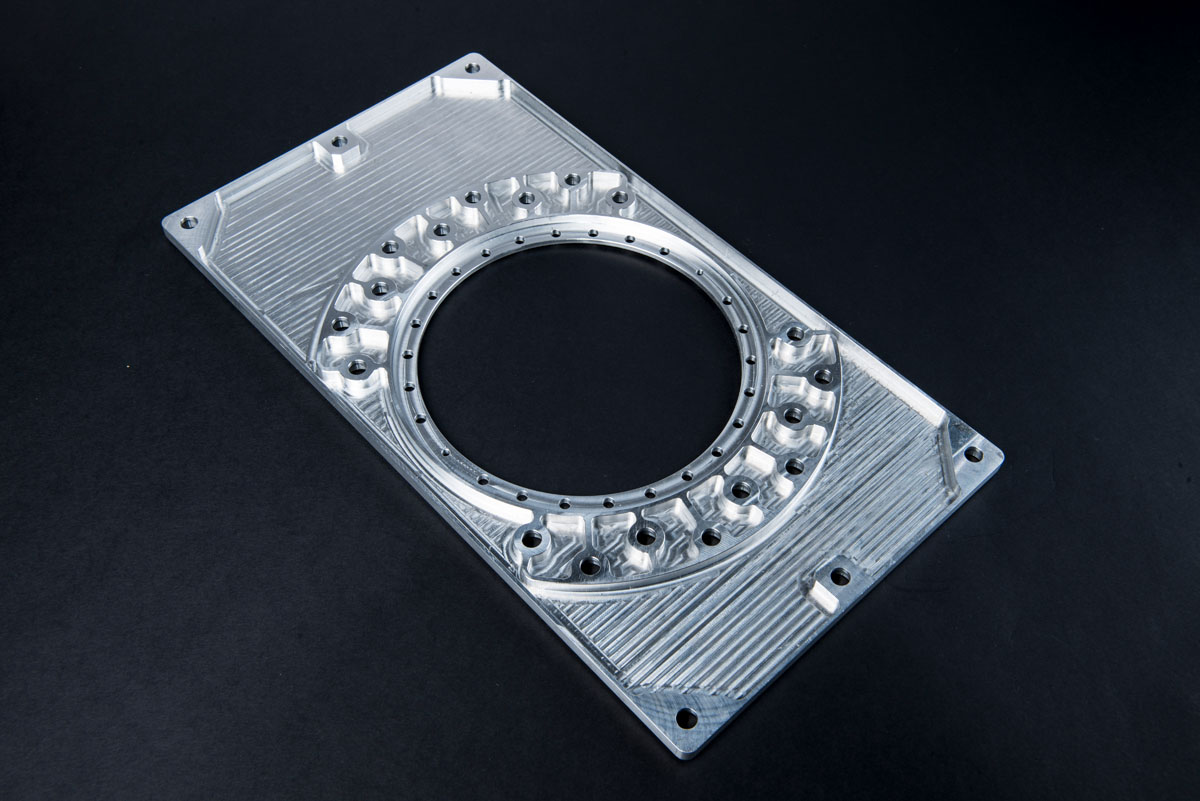

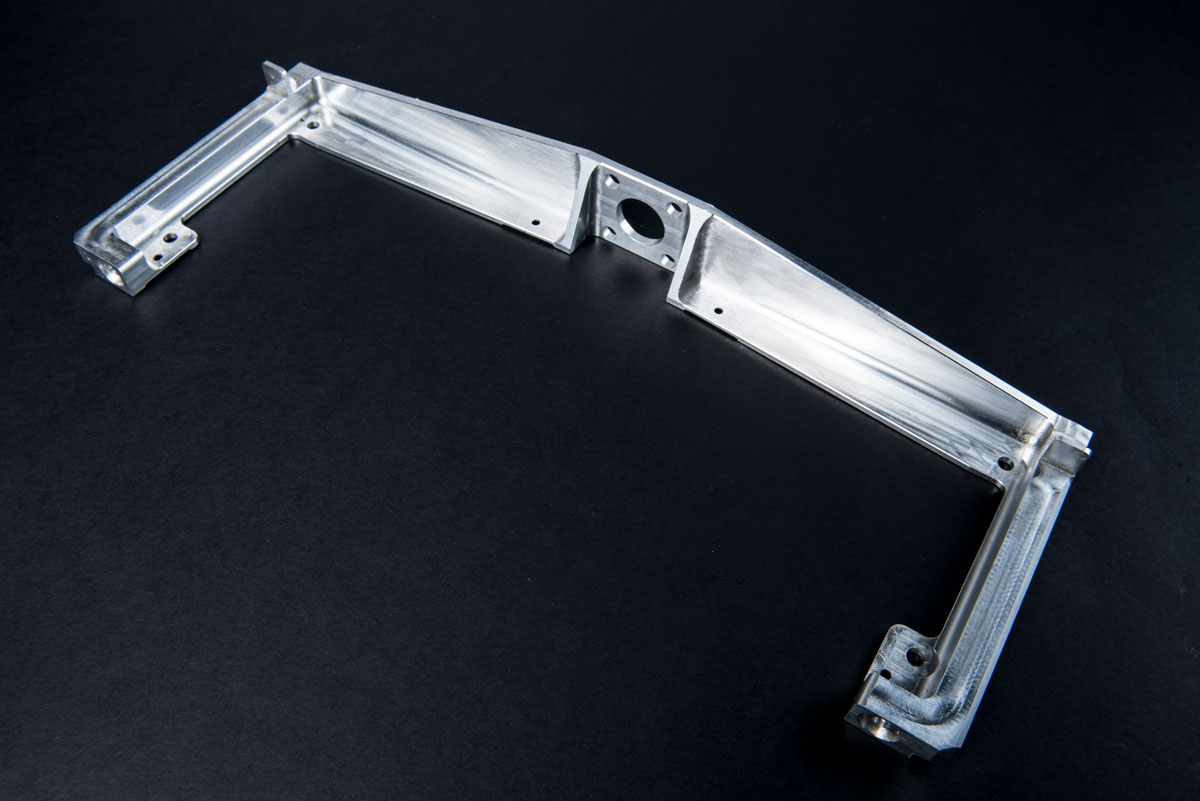

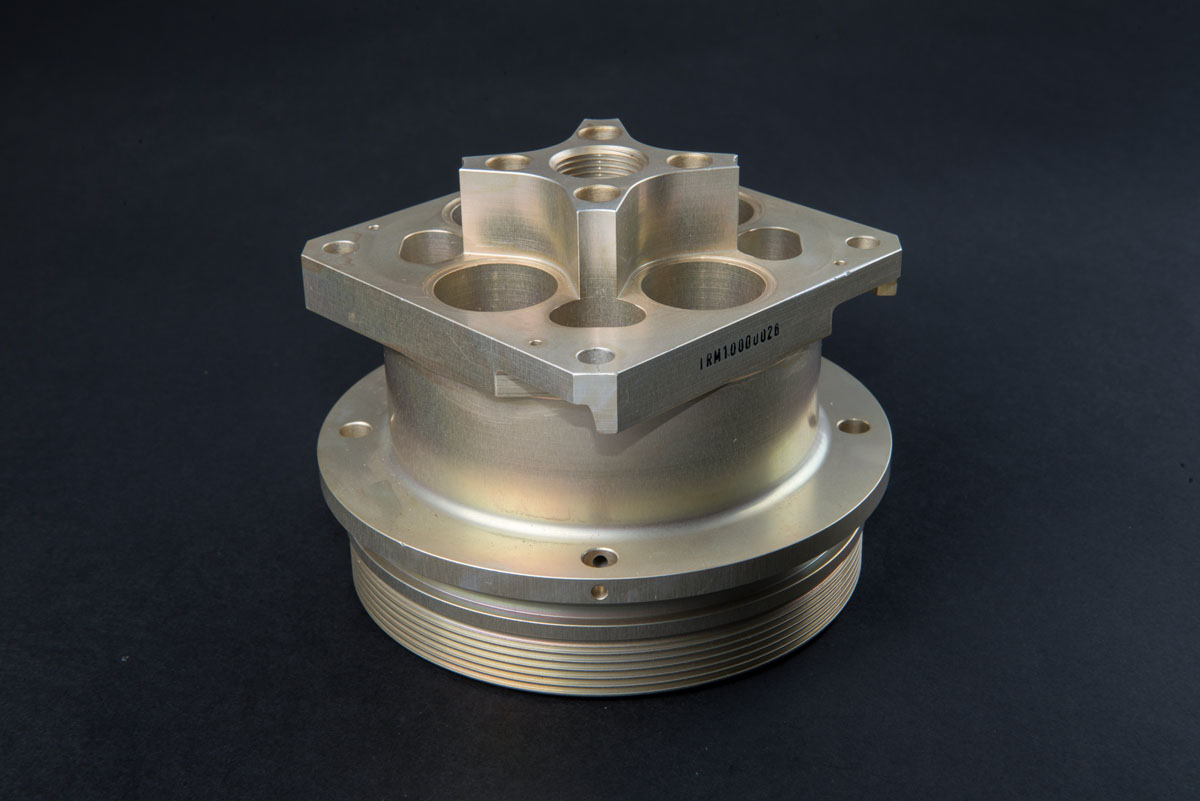

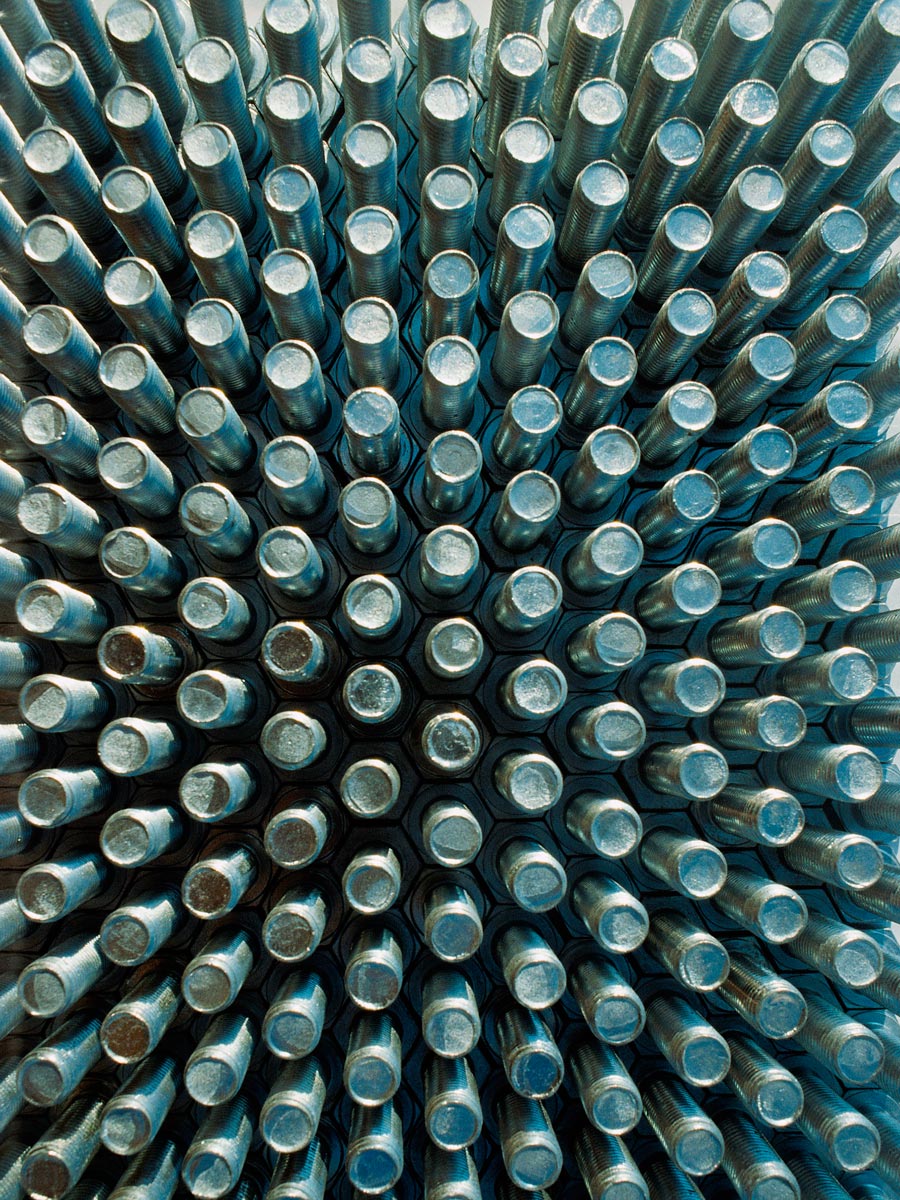

MOREWe perform precision machining with swarf removal on behalf of third parties. These parties include the aerospace and aeronautical sectors, as well as military, automobile, energy and industrial automation.

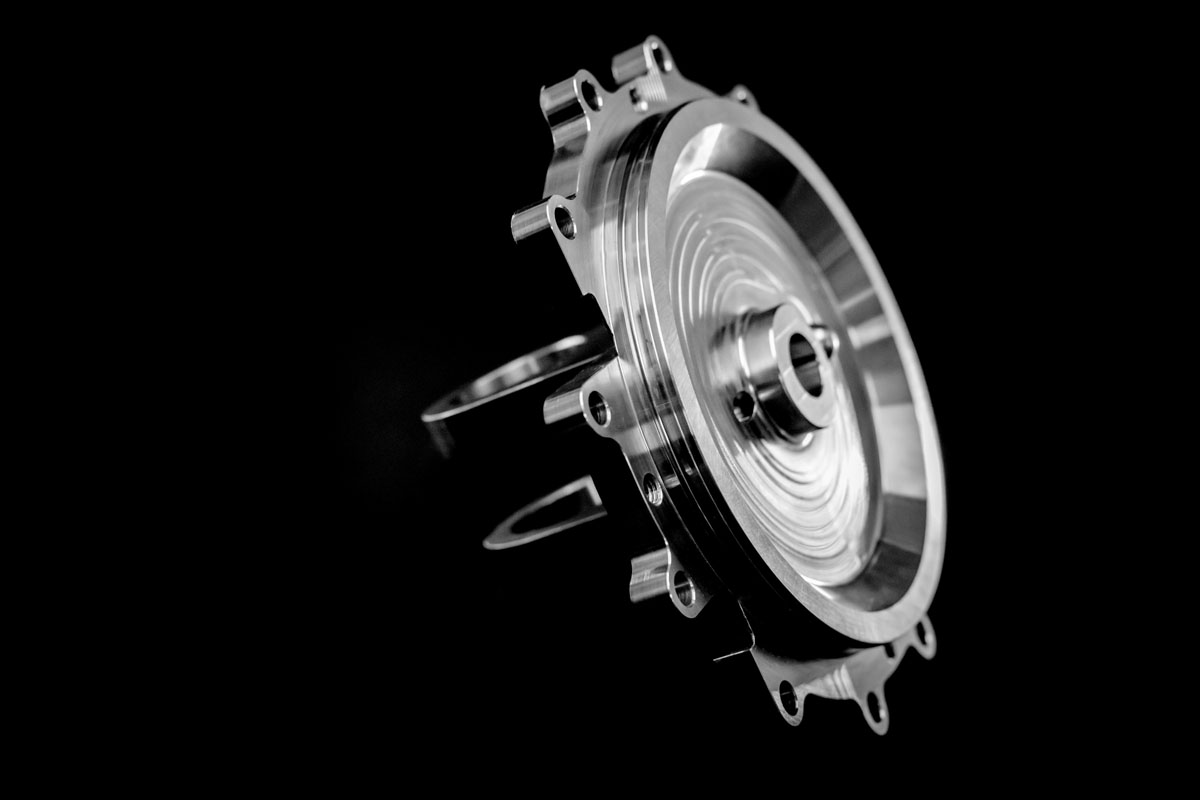

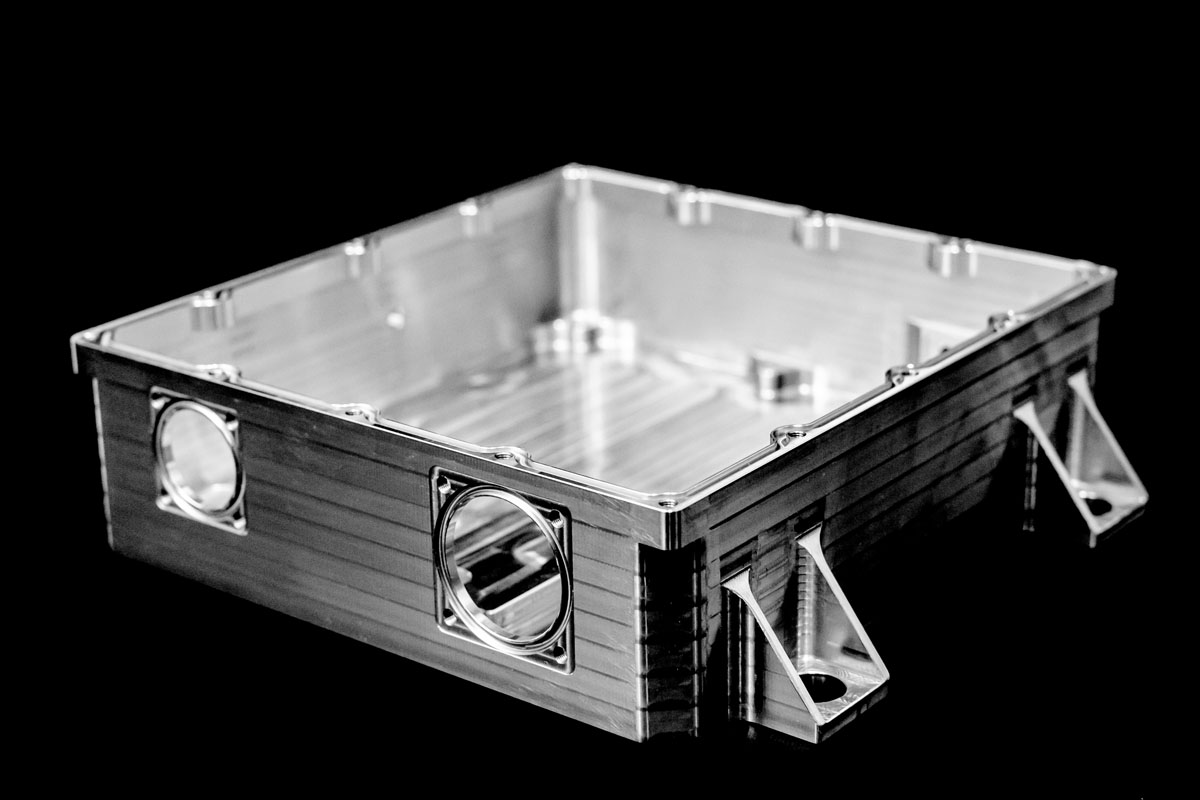

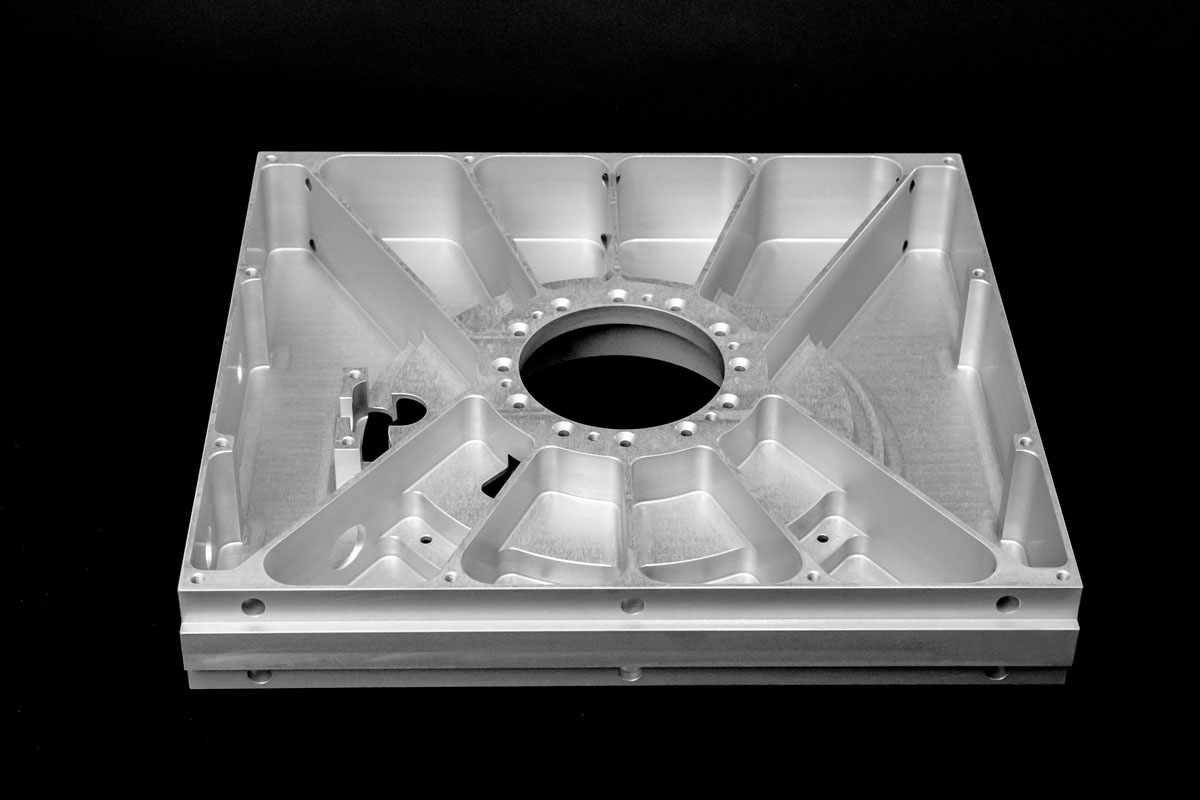

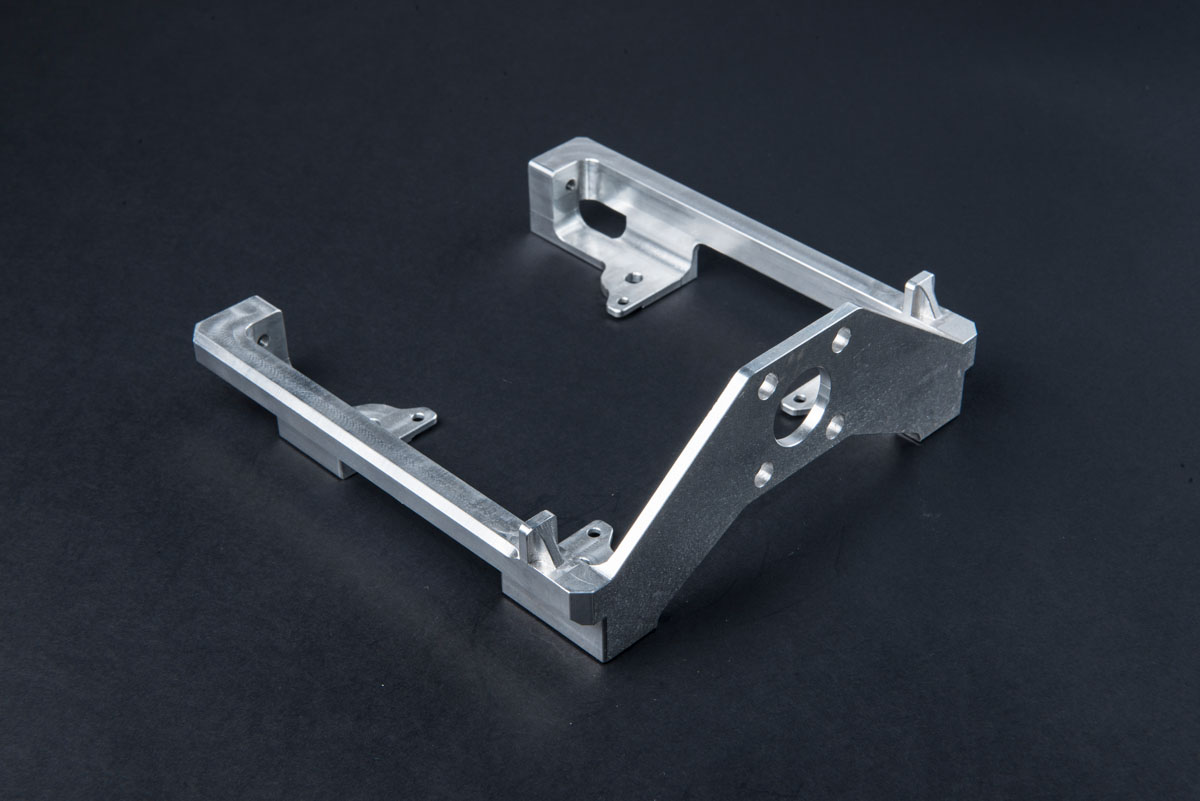

We possess the technology and the know how to produce small and medium mechanical parts using turning and milling methods, even those of increased complexity.

We carry out prototyping.

We perform dimensional checks for third parties.

We design parts and/or mechanical assemblies.

We are able to perform non-destructive checks, and surface and thermal treatments in collaboration with certified suppliers.

WE HAVE BEEN PRODUCING PRECISION MACHINERY SINCE 1986.

FIND OUT MORE

Mec.Ma.Srl was born as a natural progression of more than twenty years’ experience in precision mechanical manufacturing acquired by the founder in a company operating in the military sector.

MOREWe have a temperature controlled metrology lab in order to ensure measurements of extremely high precision. The lab performs dimensional and geometrical testing of products using two CMM measuring machines capable of working up to 1000x500. The range is completed by projectors, roughness testers, hardness testers and hundredths and thousandths instruments.

Our quality system is certified in accordance with ISO 9001-2015 and EN9100:2018 / AS9100D from the Intertek institution.

We possess our license according to article 28 of T.U.L.P.S. (Consolidated Law on Public Security) released by the prefecture of Frosinone for the manufacturing of inert metallic parts for the military sector.

Department specialized in the manufacturing of mechanical parts in aluminium alloys, high and medium resistance steels, superalloys, titanium alloys, plastic material, etc.

We have high quality turning and milling centres with numerical control. Traditional grinding machines, turning lathes and manual milling machines are also included amongst our instruments.

Milling up to 1650x700

Turning up to Ø500x1000

The Manufacturing Design and Engineering Department elaborates working cycles and programs for numerically controlled machinery.

It also conducts analyses and designs for the production of special instruments and apparatus both for internal and third party usage.